Manufacturers embrace Advanced High Strength Steels as a cost-effective way to satisfy functional and regulatory requirements. The following are just a few examples where automakers have attributed improved performance and lightweighting due to the use of these advanced steels. KIA EV9 The Kia EV9, Kia’s first three-row electric flagship SUV, is based on the Electric […]| AHSS Guidelines

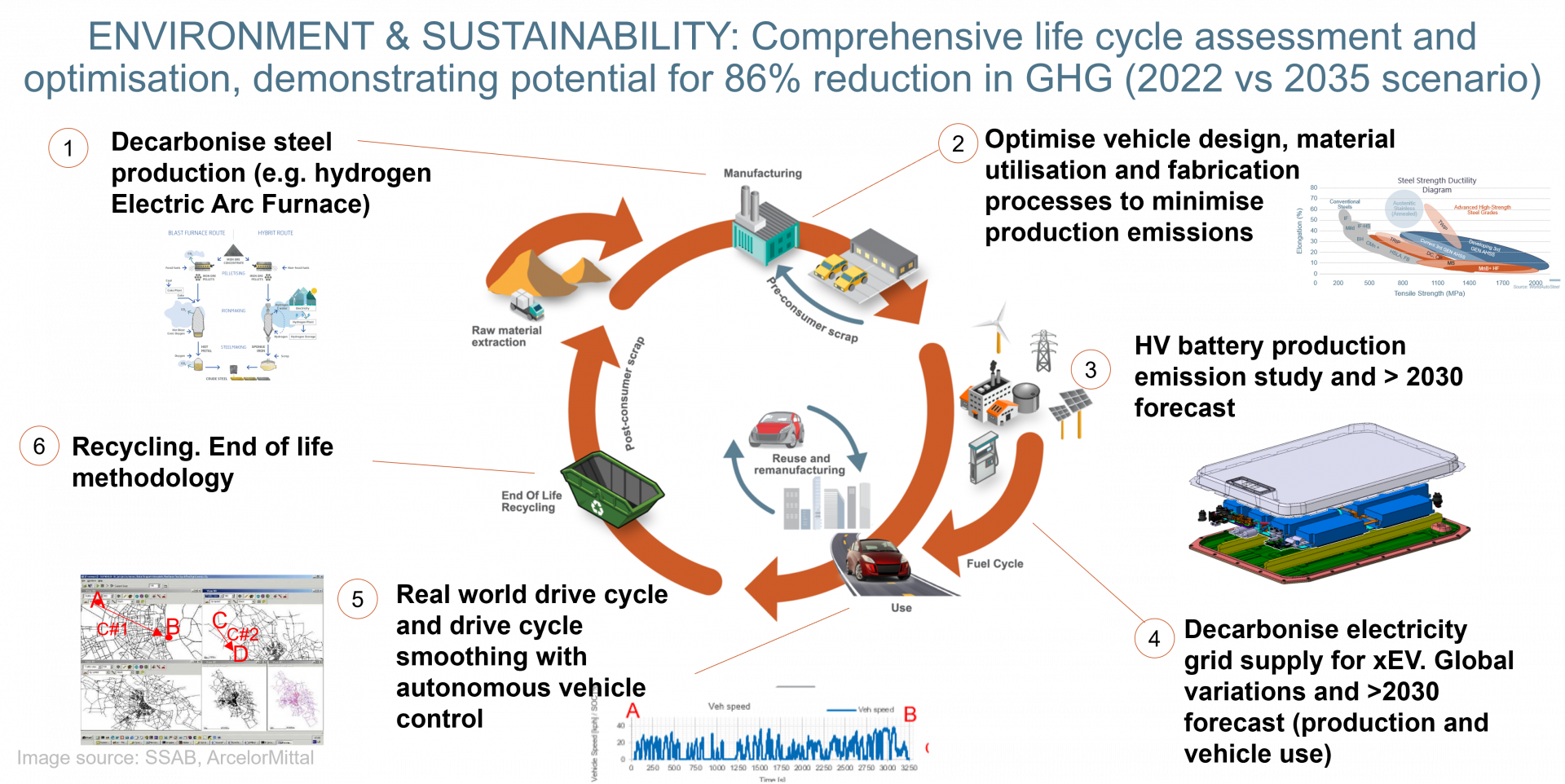

Steel E-Motive represents a fully autonomous ride sharing vehicle concept showcasing the strength and durability of steel with a critical focus on sustainability for reaching net zero emissions targets. The results are comfortable, safe and affordable body structures that support automakers in the continued development of Mobility as a Service (MaaS) ride sharing models. The […]| AHSS Guidelines

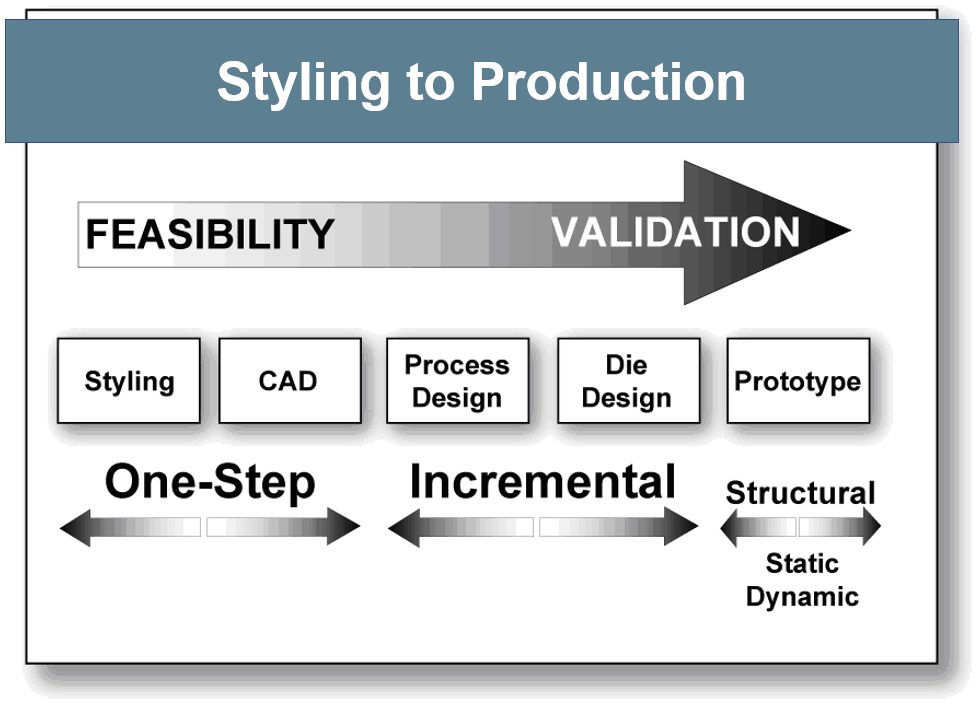

Evaluating sheet metal formability using computer software has been in common industrial use for more than two decades. The current sheet metal forming programs are part of the transition to virtual manufacturing that includes analysis of casting solidification and rolling at the metal production facility, welding, moulding of sheet/fiber composites, automation, and other manufacturing processes. Computer simulation of sheet metal forming is known by several terms, including computerized form...| AHSS Guidelines